January 14, 2026 Insights

Effective Water and Wastewater Construction Unlocks Opportunities

At the heart of every water project is a growing community.

“When we take on new construction or renovation of a water or wastewater facility, what we're building at the end of the day is clean water for that community,” says Joe Mellon, Chief Operating Officer of Shook Construction. “A certain amount of clean water must be available within a community to allow the surrounding cities to expand and grow.”

Water resource projects include both the renovation of existing water and wastewater treatment plants and the construction of new ones. A well-constructed water resource project creates a lasting impact as it takes dirty water and turns it into a consistent source of clean water, an essential resource for communities.

“Without addressing the critical needs of reliable water and effective wastewater management, communities can't grow or add infrastructure. Renovating or upgrading facilities ensures what they have is up to the new standards with better technology to deliver safe drinking water. It also provides the ability to attract businesses dependent on access to reliable water resources,” says Eric Reese, Shook Construction’s Director of Preconstruction Water Resources.

Detailed Coordination Makes the Difference

Water and wastewater facilities are often designed for a 30- to 40-year life cycle. Given that lifespan, projects are intricate with many details to sort out — from the physical building of the facility to the installation of the latest technology, including safeguards to protect the plant and its equipment from physical and online threats. Projects can span anywhere from 12-48 months, or more, and require detailed coordination of design, engineering, skilled labor, and materials.

Continuous estimating and monitoring of material costs is important for projects of this magnitude. Establishing a budget early in the design phase allows teams to determine the right design and the ability to construct the project on time. It also gives the owner confidence in a true budget and how the project will progress.

Bringing together the design, engineering, and client teams before construction begins ensures a well-planned approach. Coordination allows the teams to address budget questions, permitting, constructability of the design, proper site planning, coordinating with existing plant operations, and how best to sequence the work — all important decisions that must be made to build something of this scale and complexity.

It's this early and continuous collaboration that pulls it all together.

Benefits of Continuous Estimating and Value Engineering

The concept of continuous estimating is critical for giving owners a constant barometer on where the project budget stands. When an owner comes with an idea and wants to understand its cost implications, for example, the team can pivot and provide the latest pricing on materials, equipment, and labor to make an informed decision.

Value engineering is another key part of the process. Value engineering is the critical evaluation of all the components and scope of the project, allowing the designers and the owner to understand where cost savings can be realized while maintaining quality, safety, and performance.

Understanding the full scope of costs isn’t a one-and-done process. Teams are constantly evaluating materials and labor costs throughout a project. Proposed small changes in materials or building process phases provide the data clients need to evaluate cost-saving opportunities, with freed-up budget being reinvested into additional features or upgraded equipment. By utilizing value engineering methods, teams stay on track to finish the job on time and on budget.

Leveraging Digital Modeling

Using Building Information Modeling (BIM) and continuously updating digital models to reflect the actual conditions of the project, known as the as-built version, is a collaborative process. Working with the construction and engineering teams and the facility owner, the team inspects every section of the design and every change order, so they are constantly thinking about how to adapt to changes and how best to plan out the people and resources they're going to need. An updated as-built, 3D BIM model allows owners and engineering teams to explore concepts digitally, providing the opportunity to work out changes and adaptations efficiently in a digital environment.

3D digital models offer teams the ability to look inside closed systems and zoom in on specific details to identify potential problems months in advance. Teams can avoid roadblocks that stop work or delay installation of pipe or equipment, for example. 3D modeling allows construction teams to troubleshoot and plan the coordination of trades, equipment, and materials.

“Using 3D modeling also allows us to add the required equipment and materials into the model to create an updated plan for what’s being built,” says Aaron Crutcher, Shook Virtual Construction Engineer.

Teams also use 3D modeling to experiment with ideas throughout the building process or to think through challenges without impacting project timelines or materials. Once design changes are agreed upon within the construction plan, estimating software can quickly generate updated costs, allowing for budget decisions.

This early intervention is a significant driver of budget and time savings for owners.

Collaboration and Communication Are Key

An often overlooked but critically important aspect of any building project is the working relationships between the owner, builder, designer, and facility teams. At the end of the day, everyone involved should be working toward a common goal. Water and wastewater projects are often a multi-year process, making open communication and relationships essential.

“What’s absolutely critical is developing a regular communication process with owners and engineers,” says John Cleveland, Shook’s Director of Water Operations, Midwest Region. “Providing constant feedback on design or material changes and work progress supports a collaborative process that gains an owner's trust and shows that you’re looking out for their best interests.”

A true partnership begins at startup and continues well after the turnover of the facility.

“We are constantly challenging our project teams to look down the road to make sure that we are not only focused on an efficient building process, but how the plant will be operated and maintained going forward,” says Mellon. “When we complete a project, we want to hand over the facility not only having achieved the project goals, but in a way that allows the facility management to operate, maintain, and troubleshoot any issues.”

Co-Op Site Visit: Greene County NW Regional WTP

July 21, 2023News

Co-Op Site Visit: Greene County NW Regional WTP

July 21, 2023News

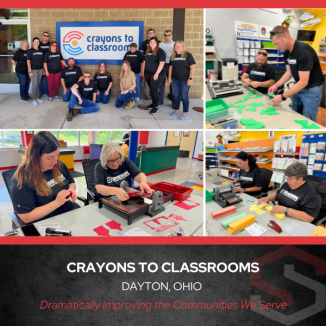

Volunteering with Crayons to Classrooms

July 20, 2023Mission

Volunteering with Crayons to Classrooms

July 20, 2023Mission

Shook is a Best Place to Work in Dayton!

July 19, 2023Awards

Shook is a Best Place to Work in Dayton!

July 19, 2023Awards

Volunteering at One Bistro

July 18, 2023Mission

Volunteering at One Bistro

July 18, 2023Mission

Drink Local. Drink Tap. Beach Cleanup

July 13, 2023Mission

Drink Local. Drink Tap. Beach Cleanup

July 13, 2023Mission

Northeastern Local Schools - Kenton Ridge PK-12 Update

July 12, 2023News

Northeastern Local Schools - Kenton Ridge PK-12 Update

July 12, 2023News

Harry F. Gaeke Memorial Scholarship Recipient 2023

July 7, 2023News

Harry F. Gaeke Memorial Scholarship Recipient 2023

July 7, 2023News

University Hospital - St. John Medical Center Site Visit

July 6, 2023News

University Hospital - St. John Medical Center Site Visit

July 6, 2023News

Victory Project Students Tour Dayton Public Schools' Welcome Stadium

June 30, 2023Mission

Victory Project Students Tour Dayton Public Schools' Welcome Stadium

June 30, 2023Mission

City of Dayton - Total Phosphorus Treatment Project Update

June 28, 2023News

City of Dayton - Total Phosphorus Treatment Project Update

June 28, 2023News

Proud Sponsor of Drink Local. Drink Tap.'s 4 Miles 4 Water

June 27, 2023Mission

Proud Sponsor of Drink Local. Drink Tap.'s 4 Miles 4 Water

June 27, 2023Mission

Shook Named Top Workplace in Cleveland 2023

June 26, 2023Awards

Shook Named Top Workplace in Cleveland 2023

June 26, 2023Awards