Our Value

Collaboration & Innovation

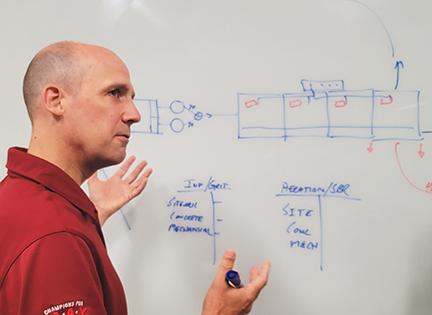

Preconstruction

Acting as an extension of our clients’ staff, our integrated preconstruction and construction team provides meaningful cost, schedule and constructability input throughout the design process. We focus on gaining an understanding of your goals, working with you and the designer to create a program that will meet your budget. Then we plan all aspects of your project, working towards efficiency in construction by anticipating and mitigating issues that could arise from existing conditions and coordination errors or omissions.

Interested in being added to our bidders list for project pursuits? Email us at estimating@shookconstruction.com.

Given the nature of the design development process, our continuous estimating approach relies heavily on our ability to perform “conceptual estimating.” This is the process of utilizing our market-specific expertise to fill in the gaps that exist early in the design process, ensuring accurate estimates that enable collaborative, informed decision-making.

Our preconstruction group maintains a team of 18 full-time estimators dedicated to the front-end planning of our client’s vision. Many of these teammates are specialists within a specific division. This dedicated focus enhances the accuracy of our estimates and the value we provide in the early phase of a project.

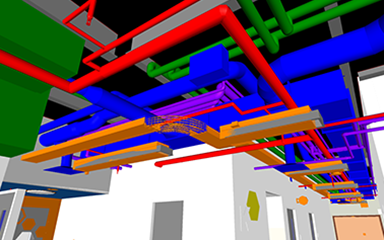

BIM/VDC

Building Information Modeling (BIM) is the process that goes beyond two-dimensional CAD by imbedding information into model components to create intelligent building systems that can be leveraged for increased productivity and project insight.

Virtual Design & Construction (VDC) is the process that uses modeled content as a way to optimize project planning by mitigating risks and improving methodologies long before construction begins. By using highly technical BIM/VDC processes, we increase our team’s ability to visualize, analyze, plan and manage complex projects—on time and on budget. Through the implementation of these processes, we can increase our effectiveness as planners and construction managers. Ultimately, the client benefits the most from our use of these processes.

Our BIM/VDC services include:

- Visualization

- Construction Sequencing

- Site Logistics & Safety

- Laser Scanning

- Trades Coordination

- Prefabrication & Lean Strategies

- As-Built Documentation

- Facilities Management

Collaborative Project Delivery

Collaborative Project Delivery is our proprietary process that allows us to properly plan, execute and deliver with ease and efficiency. Utilizing our scheduling process in tandem with our in-house model creation, we ensure our project teams are continuously looking ahead and streamlined for the approach.

Integral to the CPD process, we build models at the same time we're building the schedule in order to have a visual reference for planning. Built in-house by our project teams, the model leads to better coordination for everything from equipment to materials.

We lean on the entire project team to ensure we have an accurate sequence and the correct duration. The team continuously resource loads everything from labor to equipment needs, providing a clear picture of how the resources are being coordinated.

Lean Construction

We use Lean processes to deliver our client's projects more intelligently and efficiently. Emphasizing customer value, our Lean principles are anchored in continuous process improvement, fostering collaboration within project teams and the adoption of new technologies that enable us to work smarter.

Project Specific Prefabrication™ (PSP™) is the process of building components of a project offsite while the core construction process is underway. PSP™ ultimately leads to increased productivity and shortened schedules, but also leads to a cleaner site and better construction quality.

Pull-plan scheduling is a Lean form of scheduling. It works where the date required for the project to finish is established and you “pull” back the tasks to ensure a correct and efficient schedule for the project prior to commencement. This form of scheduling is more accurate and better suitable during the construction progress than conventional “push” style scheduling such as P6 or Microsoft Project. It also allows for team communication and accountability between owners, engineers, and subcontractors which fits perfectly into Shook’s collaborative approach to delivering projects.

Quality Control

At our core Shook is a builder. Our teammates don’t simply manage process, we show up to work everyday to move dirt, lay pipe and swing hammers. This identity comes with a higher expectation for putting the work in safety and correctly. It is personal. We use a multi-pronged playbook of communication, clear expectations and rigorous inspections to ensure the work is put in place correctly, every time.

Our quality control process relies heavily on the use of mock-ups that represent a fully constructed representative of the design. We utilize this strategy for building components that range from curtain wall sections to roofing details or fully finished patient rooms. This allows us to verify the function of design and provides end-users the opportunity to approve finish details that they can see and touch rather than having to visualize abstractly.

We utilize a first-work process for quality control that validates the quality and specification compliance of the first piece of work put in place. Once the work is approved this becomes the standard by which all future components are measured. This approach clearly communicates standards and removes ambiguity about what is considered acceptable.